Processes optimally linked

STIHL Tirol: Fully automated AutoStore warehouse

In 2019, STIHL Tirol added an extension to its competence and manufacturing site for ground-guided garden tools in Langkampen. A special feature of the new building is the fully automated small parts storage area – one of Austria’s most modern storage systems. The AutoStore technology not only makes logistics much more efficient, but the storage are also used in a particularly space-saving way thanks to a shaft design with 57,000 containers. A total of 26 robots are in use in the small parts storage area.

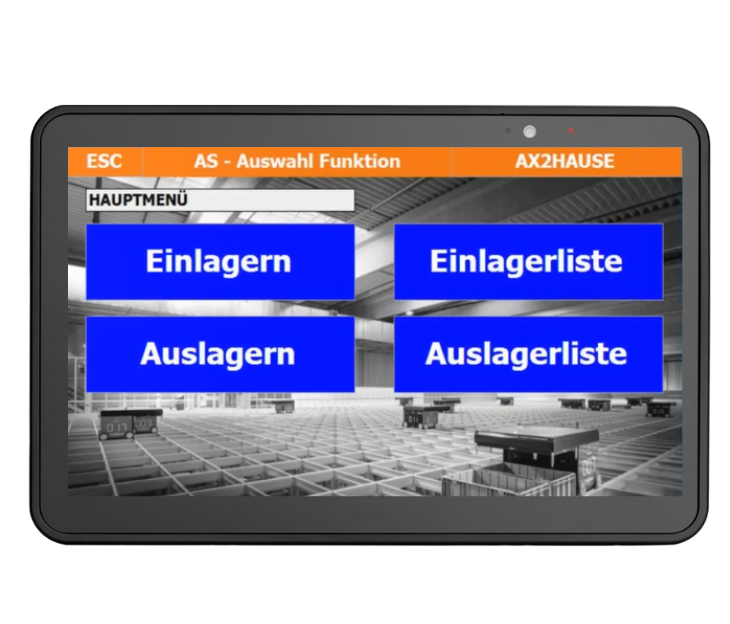

With the direct connection of MSB to AutoStore, warehouse employees can execute all processes directly in SAP on the mobile device via the MSB app.

About STIHL Tirol GmbH

STIHL Tirol GmbH was founded in 1981 as VIKING GmbH in Kufstein, Austria and has been a 100 percent subsidiary of the STIHL Group since 1992. At the Langkampen production site, battery-powered products are manufactured and co-developed. STIHL Tirol is also the competence center for ground-driven garden equipment such as lawn mowers, robotic lawnmowers, ride-on mowers or garden shredders.

The family-owned company attaches great importance to entrepreneurial and social responsibility. STIHL Tirol meets this requirement with voluntary social benefits for its employees, first-class training places or local social commitment. Long-term sustainability, resource-saving production as well as STIHL products with integrated environmental protection contribute to STIHL Tirol’s understanding of sustainability.

The STIHL Group, headquartered in Waiblingen, near Stuttgart, develops, manufactures and markets motor-driven equipment for forestry and agriculture, landscape management, construction and private garden owners. The products are distributed via the service-providing specialist trade and STIHL’s own online shops – with 42 own sales and marketing companies, around 120 importers and more than 55,000 specialist dealers in more than 160 countries.

Company Facts

-

Production site for battery-powered products

-

Competence center for ground-based garden tools

-

More than 770 employees

-

Over €715 million in sales in fiscal 2021

Industry

MSB in use

Logistics, Production

Automated Logistics Processes

System integration focuses on the main process: The production supply. The company faced the following challenges:

- Complex processes: Simplify and accelerate existing logistics processes

- SAP as the leading system: No third-party system in which data is held is to be used

- Lack of user acceptance: Confusing screens make working in logistics difficult

This was implemented:

The AutoStore can be connected to SAP either via a middleware or directly. With the mobisys SAP add-on – Mobisys Solution Builder (MSB) – STIHL Tirol already had the right solution in use in logistics (goods issue, production supply). One advantage: With the direct connection of the AutoStore via MSB, SAP remains the leading system.

Processes such as putaway can be executed by the warehouse employee directly in SAP on the mobile device via the MSB App. For example a storage order is forwarded to the AutoStore controller via SAP and executed by the corresponding robots: An empty AutoStore container comes in and an empty storage bin is displayed to the employee.

- All data in one system, simple evaluation directly in SAP

- Maintenance and changes are in the hands of the company and can be done easily and quickly

- Reduced and clear MSB user interface for efficient processes

Benefits for Nussbaum

- High data quality through direct connection of the AutoStore to SAP

- Process security: Low error rate through seamless process & system integration

- Save time and increase productivity: Optimally linked processes and fast execution of tasks through mobilization

- High user acceptance: Satisfied users through optimal usability

”With MSB as logistics software, our employees can communicate directly with the AutoStore warehouse via simplified screens. SAP remains the leading system with all master data. We have found a very user-friendly and stable solution.

Beat BobstHead of production, R. Nussbaum AG